Design

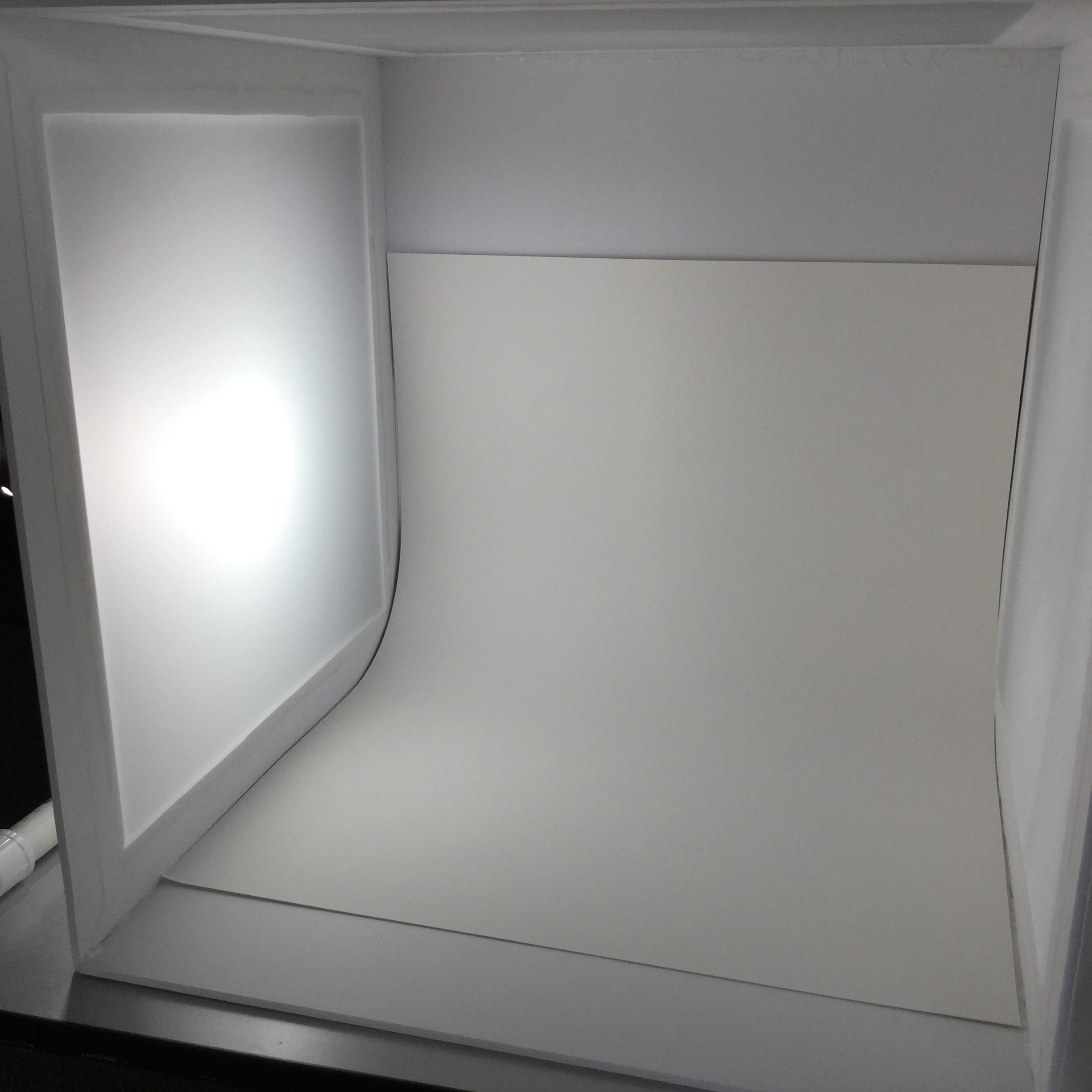

Lightbox v1.1 was constructed similarly to our first lightbox, with some minor differences.

Left: new lightbox, Right: original lightbox

The new lightbox is also constructed from foamboard, posterboard, and a semi-translucent material. The foam board was joined together with hot-melt adhesive (also known as hot glue) rather than duct tape. To reduce waste, the windows panel frames were made from 2 inch strips of foam board, rather than cutting squares out of whole sheets. The construction method is detailed below.

Construction

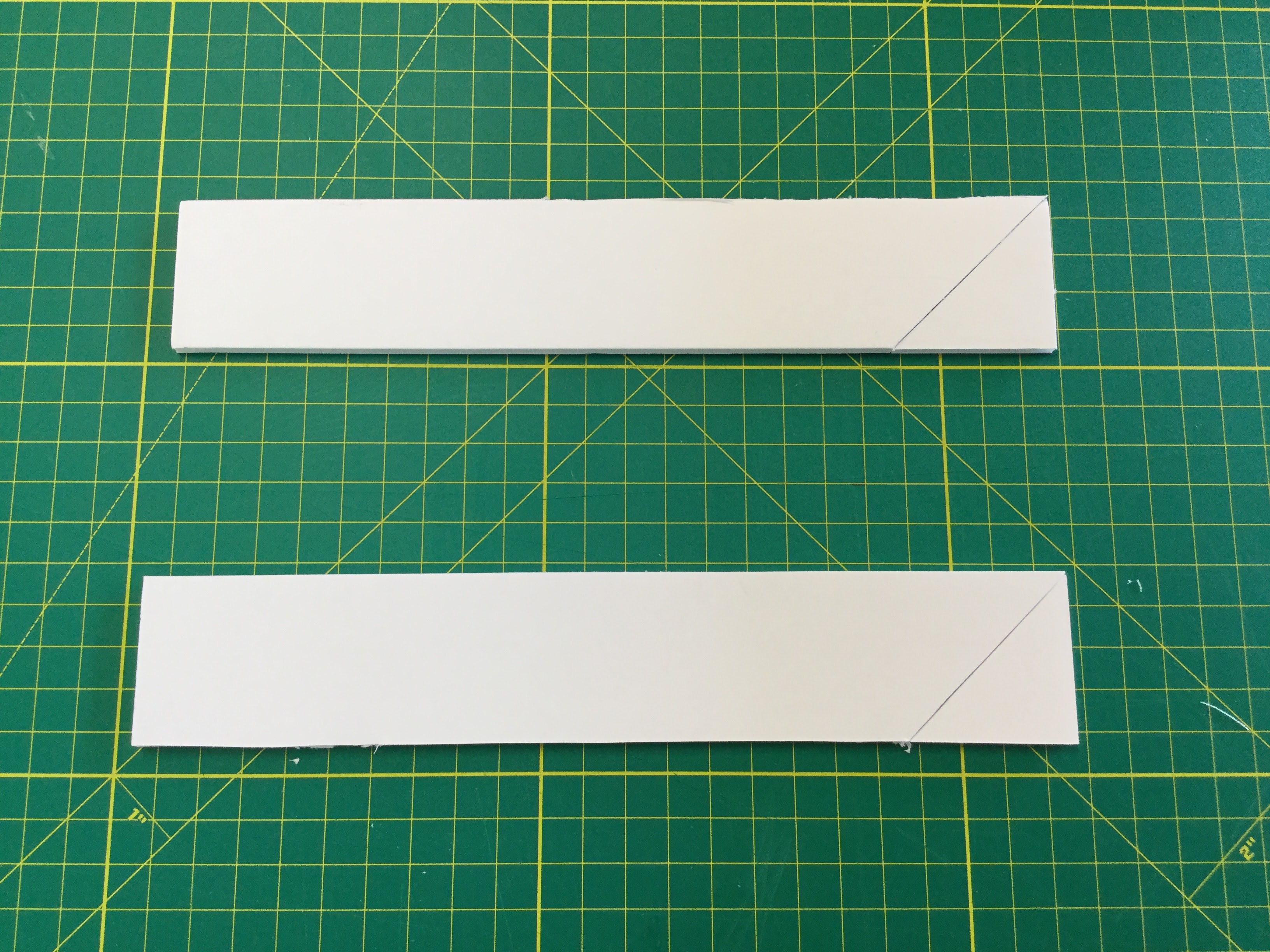

A knife was used to divide sheets of foam board into 2 inch strips, 20 inches long. A 45 degree cut was made on both ends of each strip. In this example, shorter pieces are used to demonstrate the process.

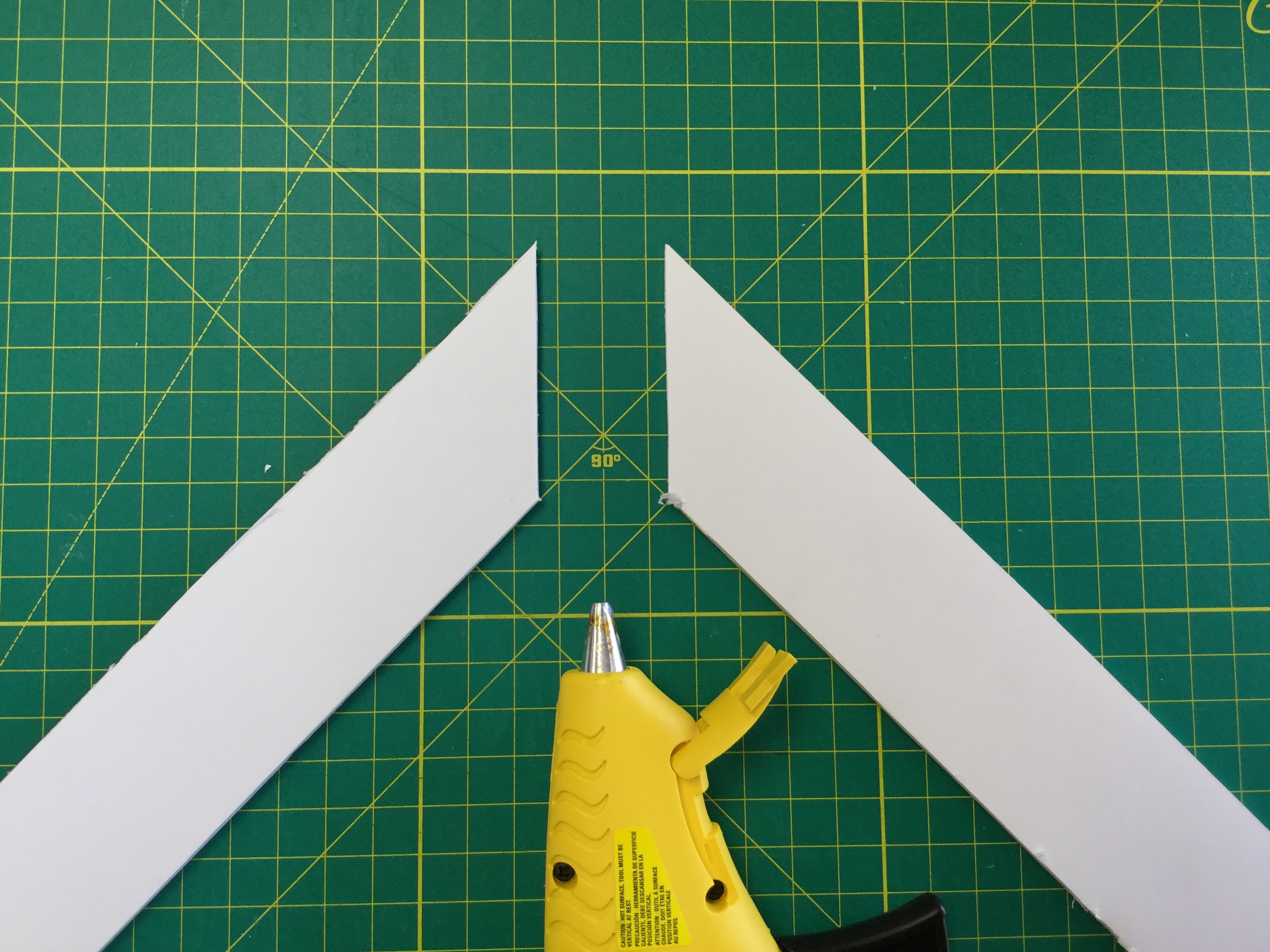

After the ends of each strip are cut, hot glue was used to join the foam edges of the strips to form the corners of the frame.

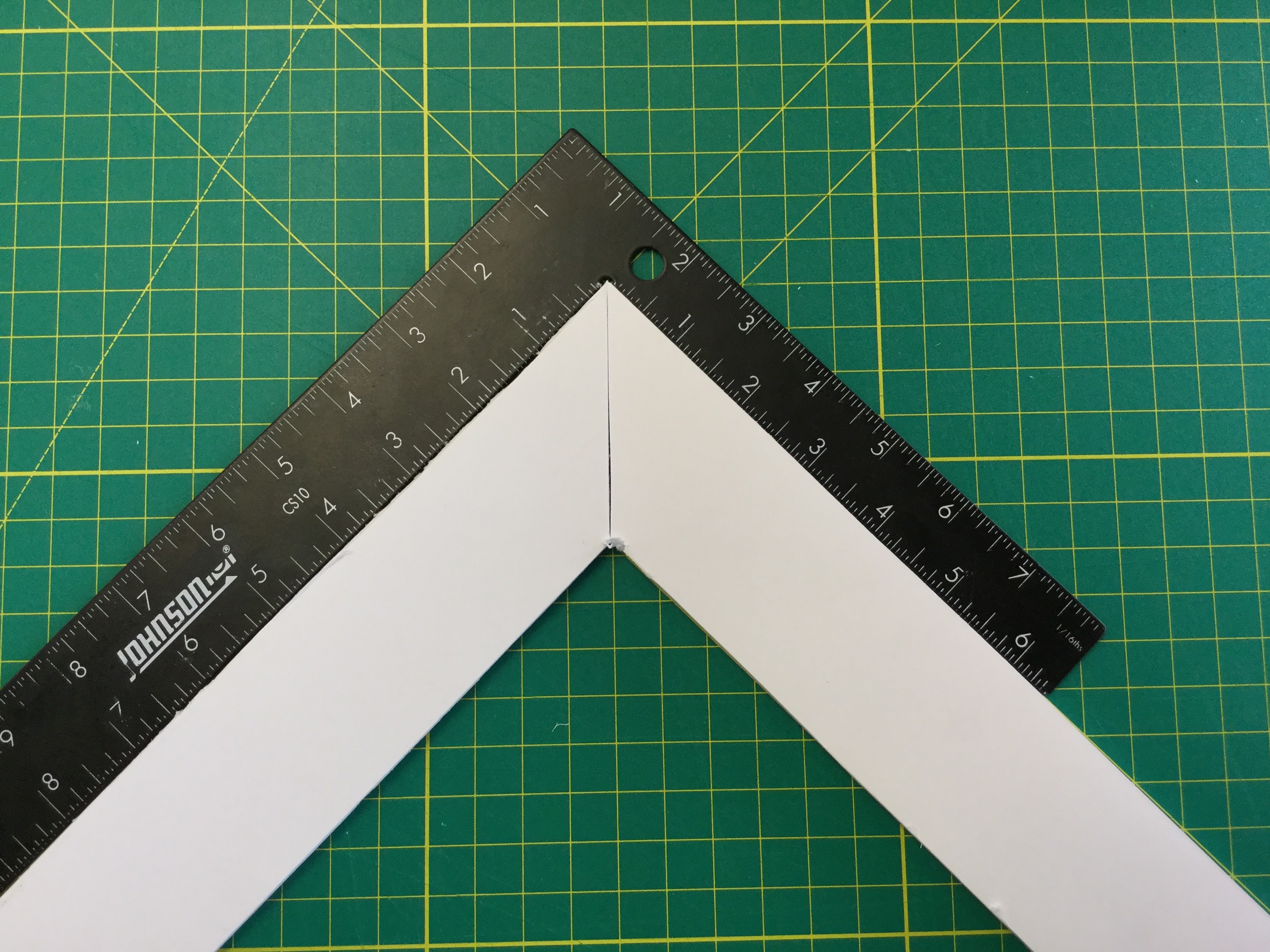

A square was used to ensure that each strip was joined at right angles to make sure the frames of the box fit together properly.

Details

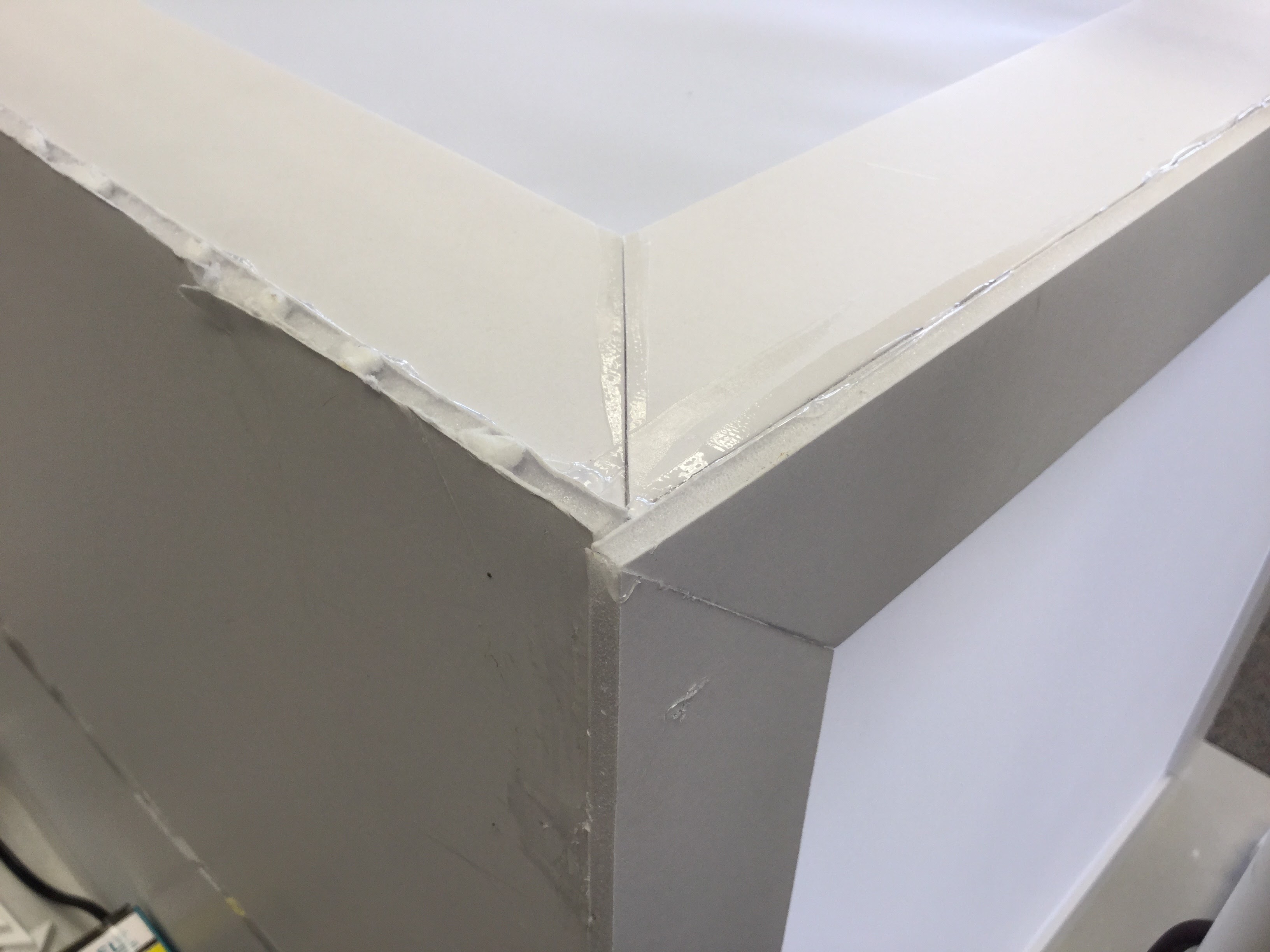

To join the 5 frame pieces together, hot glue was used to join the edges together. Excess glue was spread along the edges to increase strength.

In the first lightbox, the fibers in the cloth are visible and the material does not disperse the light as evenly, resulting in a more focused spot of light.

The translucent material used is 0.003 inch thick matte drafting film. For the window frame panels, the film is glued onto the inside of the frame.

The drafting film allows the light to diffuse more evenly, resulting in better picture quality.

He has been a Master Builder in buildIT from 2014-present.

Joey built his personal 3D printer in 2014.

- Lightbox V1.1 - June 22, 2016

- Layer Height - June 2, 2016

- Plastic Google Cardboard - March 24, 2016