- This event has passed.

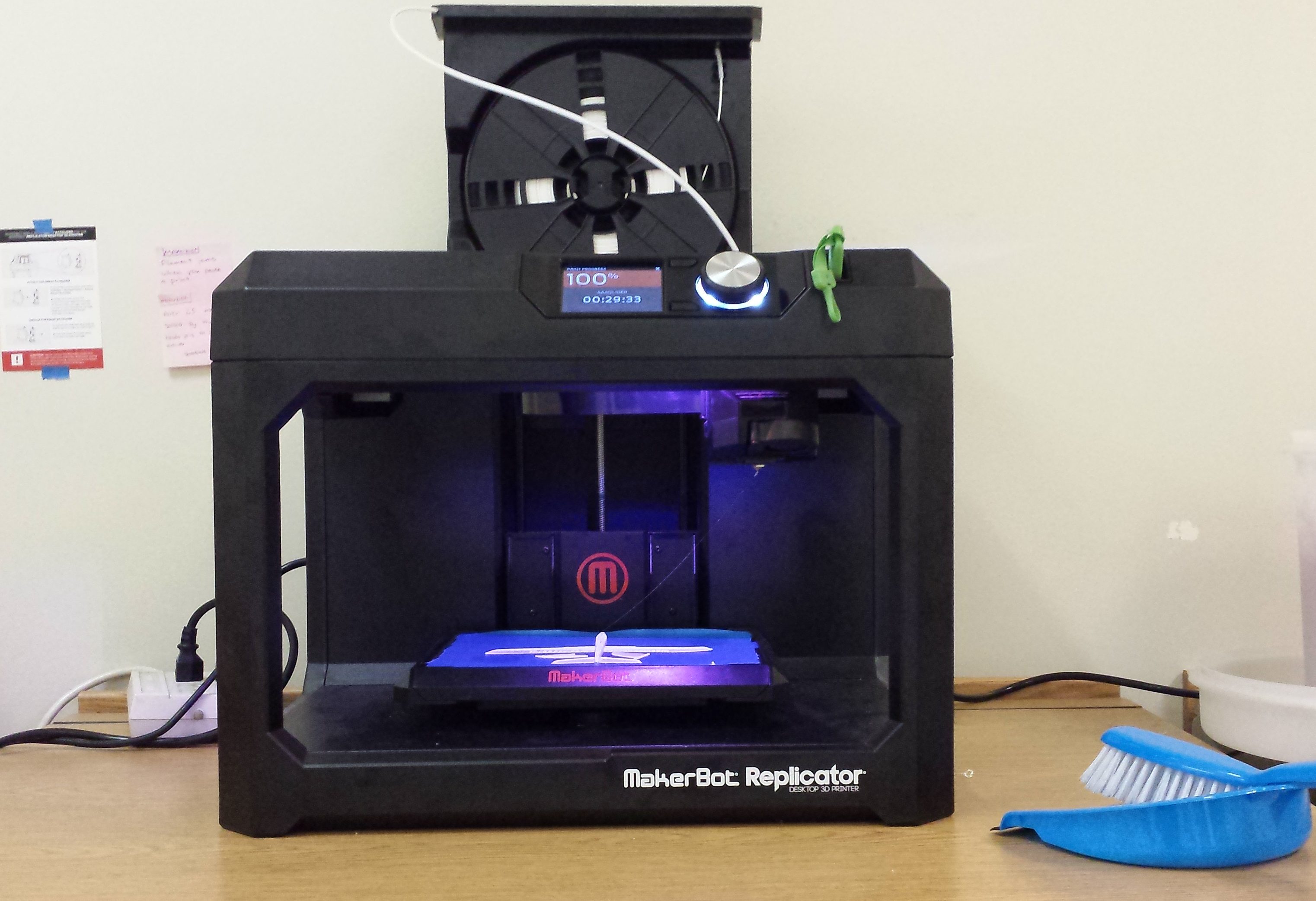

3D Printing & 3D Modeling Basics

September 20, 2016 @ 2:30 pm - 4:30 pm

A RedID is required to attend this workshop.

In this workshop, attendees will learn the basic of 3D printing and modeling. This session will cover how you can use the Makerbot 3D printer to build your own parts. To help you learn, there will be a hands-on session where attendees will design a custom keychain in TinkerCAD. After this workshop, anyone who has attended build IT’s orientation will be able to use the Makerbot 3D printer during our open hours.

Latest posts by Jenny Wong-Welch (see all)

- Halloween DIY Costume Contest 2023 - October 19, 2023

- Halloween Party 2022 - October 17, 2022

- 3D Printed Pumpkin - October 17, 2022